Welcome to

An Automobile Diagnosis Website

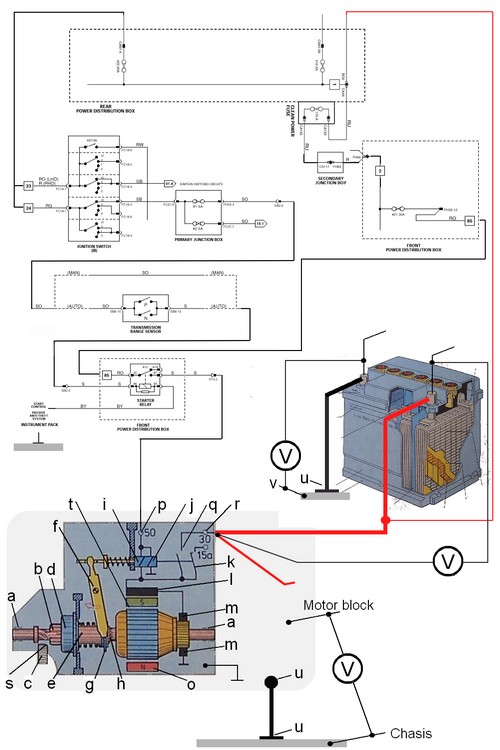

Starter system

Life has shown that old and weak charged batteries will go down in the first days of severe frost, whereby the starter clicks and clacks,

the instrument panel goes array and possibly dims. To assure oneself that the battery is the culprit, turn on head

lights (main or high beam), start again, if headlights go down, battery flat, while undercharged or defective.

Down bellow is a description of how the starter system can be diagnosed.

1. If headlights stay well illuminated, solenoid clacks, starter defective.

If starter (reachable?) hold key in starting position III, knock hefty on

starter solenoid, see if starter will crank, take care of your safety!

2. Battery power O.K, starter no click or clack, check fuses, if reachable check connection 50

solenoid, its fastening. Hold key in starting position, check voltage (>10.5V). If no multimeter

at hand, carefully, take care!! (eye protection! sparks), shortly bridge B+(30) to 50,

starter motor should engage and crank engine, if not replace starter motor.

3. With fuses checked! no or lower voltage on terminal 50, but through shorting B+(30) to 50 turned out positive,

starter engaged. Now, check starter relay (b,c), controlled through

ignition switch (pin FC18-3), if AT park, neutral switch (a) pin GB6-10, pin GB6-12, anti theft security (pin85).

a)Whilst holding ignition key in start position III, waggle (back and forth, sideways) shift level in

position P and in N (park, neutral switch), note reaction?

b)Whilst turning the ignition key start position III on/off, is there a hear-able starter

relay click? note reaction? see position (c) (reinitialize anti-theft security, lock/open car)

Hold ignition key in start position III and knock on starter relay, note reaction?, if cranking,

replace starter relay.

c)Pull starter relay, fuse checked? check if pin 30 carries B+, shortly bridge pin 30 to pin 87, see if

starter engages. See, if pin 86 has battery voltage and 85 has some Battery minus

(careful, electronically switched (use Led test lamp, anti-theft security)).

No voltage on pin 30, check fuse, connections.

No voltage on pin 86, bridge ignition starter position III, (AT) bridge transmission range sensor.

No B- on 85, possible defective start control, passive anti-theft system, instrument pack.

Starter internal problems

Problem:

Considering that battery, cable and connections are in good condition. Whilst starting, engine turns slower,

starter motor makes some kind of an inner rough grinding noise, though starting rpm are met (150-200rpm), engine starts.

Now winter comes, starter and battery are now under extreme stress to overcome the thickened motor oil,

and now to this comes the extra inner starter motor friction due to warn bushing (inner grinding noise gets louder),

starting rpm are not met, engine won't start.

Answer:

Position a,t: Worn-out brass bushing (a) especially front gear bush, whereby the armature grinds against field coil (t).

Comment:

For most starters bushes can be purchased.

Problem:

Sometimes a very loud (milling) noise occurs, which can't be over heard. Starter gear tooth presses against

flywheel gear tooth with the main power switched on too, but the gear can not swirl in, it starts to grind, mill and

therefor damage the flywheel gear teeth.

Answer:

Position b,c,d,s: Free gear worn, defective

Comment:

Repair immediately!, damages flywheel gear teeth, try to reconstruct flywheel gear teeth (key files). Replace

starter motor, if it happens again change flywheel or gear rim. It will get costly!

Problem:

Ignition key in start position III, starter motor engages/disengages repeatedly.

Answer:

Solenoid defective, (hold) windings open.

Comment:

Problem:

Holding ignition key in start position III, Starter motor clacks, knock hefty on solenoid.

Answer:

Solenoid defective, bad contacts (q), winding (-), soft iron core sticky,

Comment:

Problem:

Starter motor lacks power, stutters

Answer:

Worn out coals or seized in holder.

Comment:

Replacing coals, commutator has to be clean, and have a smooth surface.

A commutator that is not round and grooved, needs to be over turned (lath), than coals can break,

do not use file or sand paper.

The insulation material between commutator poles, should be milled or sawed half deep the width of a commutator

pole because the insulation (+ wear residues) is of harder consistence than the commutator's copper, coals will

begin to bounce (bad contact).

Commutator coals should move easily, freely in their holders.

Stark worn coals should be replaced, commutator lathed.

New coals have to fit commutator's radius.

A procedure, wrap some fine sandpaper around the collector (fasten), place a coal in a holder,

remount back cap, rotate collector back and forth.

Run in coals on work bench in an intermediate manner (keep cranking power low!), clamp and hold firmly!

Clean all heavy wire connections from block to chassis, chassis to battery, battery poles and clamps.

General Service Information

General Service InformationRear axle

Rear sub-frameFront axle

Lower ball-point joint, Shock absorber bushes, Stabilizer bar links + mountsBrake disc and pads

Engine

Intake Manifold / Ignition Coils / Spark-plugs/ engine-block ventilation (elbow)Injectors

Starter system

Valve clearance, timing-chain, tensioner and glides:

With valve clearance in its tolerance,

there was no need to take the camshafts down, so tensioners and co. have to wait, the good thing is the

tensioner pumps up in 3-4 min. the rattle noise disappears.

Cruise control malfunction, emergency mode

Automatic Transmission 5R55N

Info, tips, Fail Safe ModeStall Speed Test procedure and diagnoses

Valve Body, known issues

Valve Body, Solenoid test procedures

Line Pressure Test

Self made press for pressing down clutch drum springs, checking clutch tolerance without a dial gauge

Chassis

Air ConditioningMiscellaneous repairs

Wind-shield-wiper mechanism:

Time on the lot took its toll, wind-shield-wiper shafts had seized,

uninstalled the mechanism, freed the seized shafts through the use of a good rust loosener, heat, force.

Water in Spark-plug wells 3-2 cylinder:

After days of heavy rain the engine began to misfire with

accounted trouble codes, spark-plug wells were wet, an ionized rusty red path on the ceramic insulator had developed which shorted the

HV ignition spark.

Radio:

Connected the radio controls to the multi-functional steering wheel using

an analog digital converter.