Welcome to

An Automobile Diagnosis Website

Possible problems with the 5R55N Automatic Transmission

Info and Tips

FAIL-SAFE-MODE

When the (PCM (ECM)) detects a failure, for example, a defective input sensor(S) or signal fault,

the system may use its Failure Management Effects Mode (FMEM) strategy and produce a substitute

signal or value.

When the AT totally loses its electronic control, it will operate in a Fail-Safe mode,

with the following functions

-Maximum line pressure in all transmission Shifter positions.

-Fully functional P,R,N transmission Shifter positions.

-Operation in the 4th gear only with coast braking when the selector is in the D,3,2, or 1

positions.

-Torque Converter Clutch (TCC) will not be used.

Mechanical failure

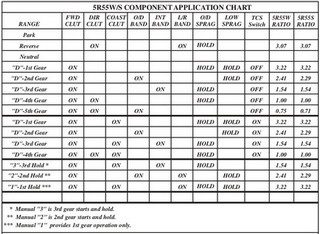

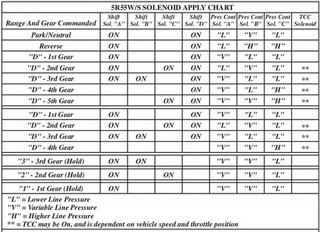

The Component Application Charts bellow shows which clutch, band, OWC(sprag), solenoid is active when a gear is engaged. This

chart is also a good trouble shooter.

Example, with the forward clutch (FWD Clutch) failing, which is needed for all forward gears (see column), no forward gears can

be engaged but the reverse gear where the power is not distributed threw the forward clutch will still be available.

Example, no reverse gear, either direct clutch, low/reverse band or overdrive (OWC) sprang slipping.

The direct clutch is also used in the 4th and 5th gear, low gear/reverse band used in manual 1st, second gear,

check if the gears engage. The Overdrive OWC (Sprag)? See what won't engage.

Best is, when the transmission starts slipping not

to drive further, this could be a minor line pressure problem which may be easy to solve but driving

further would damage clutches, bands (friction, overheating) etc. Links down below show known

problems, tests and possible cures.

1.Transmission is filled for life

Excessive condense water build-up can lead to shifting problems, when outdoor

temperatures go under (cyclical problem).

2.In severe duty Maintenance change at 48000Km (30000 miles)

3.Use WSSM2C202B ATF or others meeting Jaguar specifications, ATF Mercon V

4.Normal drain 9l, completely drained 9.5l

5.When doing a new filling, fill until the oil streams out of the oil level check plug.

ATF level check read down below.

6.Never overfill!

A good sign of extreme overfilling is when the AT-Fluid is pink coloured instead of being almost deep red

when it streams out of the level control plug. In an extreme case of overfilling

it will probably take 2x 3o min. waiting innings to let the AT-Fluid settle down,

release its trapped air bubbles and find its volume.

Repeat, refill, oil level check 2x (see down below) until the AT-Fluid streams out almost deep red.

Further, transmission could shift improper (erratic pressure).

A pink coloured AT-Fluid has tiny air bubbles whipped into it, and will therefor not behave like a hydraulic fluid,

it becomes compressible, line pressure parameters will not be met, clutches and bands slip,

overheating, damage can occur.

Power train OBD II (ScanTool DTC)

First, check for DTC, repair motor DTC first, note code(s) and delete. Get Power DTC Summaries, follow

through with all drive cycle tests.

The Comprehensive Component Monitor Transmission Drive Cycle

which will "check" all transmission system components, note, that not all AT components are monitored,

read/do down below.

1. Start engine.

2. Move transmission mode switch between Normal and Sport. Verify switch state illumination.

3. Move the gear selector to all positions in the J gate for five (5) second each. Verify switch state illumination.

4. Drive vehicle to bring the transmission fluid temperature up to normal operating temperature.

5. Stop vehicle.

6. Switch off all heavy electrical consumers: ACC, heaters, etc.

7. Transmission mode switch in - Normal.

8. Select 2nd Gear; accelerate slowly. After 5 seconds, select 3rd Gear, accelerate slowly.

After 5 seconds,

select 4th Gear, accelerate slowly. After 5 seconds, select drive; cruise at 72km/h (45 mph) for 30 seconds.

9. Stop vehicle.

10. Use the JGate to shift through all gears while accelerating briskly to 87km/h (55mph). Cruise at this speed

to allow torque converter clutch lockup to occur in fifth gear.

11. Stop vehicle and repeat steps 8 through 10.

12. Readout failure codes.

(Repeat all steps 5x)

If a mechanical fault is assumed go to (Stall Speed Test),

smell the AT's fluid, check its colour and its consistency (if ok, it is a clear and almost dark red fluid),

this however is down from underneath, at the AT's Oil Pan Drain Plug. Let the fluid stream through a

paper filter, check for metal filings, particles, fragments.

A dark coloured burnt smelling oil means some harsh slipping, friction, overheating had occurred and

may have severely damaged clutch/band linings.

For the DIY's or One's with the lac of financial acumen

If the oil is still in a good condition, the last AT service wasn't to long ago, then capture the ATF,

filter it and use it again, the pan gasket can be used again if not damaged (do not use sealant).

If the fluid needs to be replaced, capture, measure its content and replace it with the same amount/specification.

Place a large pan underneath the AT, than oil will drip out constantly.

Remove oil/pan, check oil pan for burned dark coloured crumb like particle residue, if so, (open) oil filter as well,

check for further remains of burned clutch, band linings and tiny Alu and metal fragments (hard Chrom)

from a possibly damaged bearing or Sprag etc, note, not the fine normal wear that is attracted to the pan magnet.

These are obvious signs that the AT had been severely damaged and needs an overhaul, transmission lines,

and AT cooler flushed. When, however the oil never has been better, and if everything is considered OK,

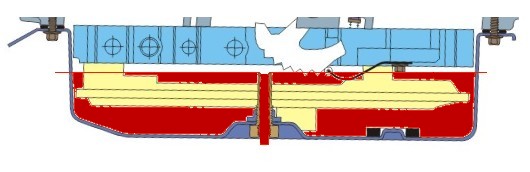

then there is a good chance that through the replacement of worn/broken valve springs and cleaning of the solenoids (VFS)

the transmission will operate normally again, than the solenoids can become sticky due to wear residues.

With (all!) the captured ATF, filtered and clean, pump it back into the transmission through the

"Fill-Plug only", located on the right hand side, above the near back end of the oil pan (Alen key) or

remove but not disconnect the back end impulse sensor and fill AT through there,

with the use of a two-way hand pump, than the catalytic converter can get very hot.

Oil level check read down below.

With ATF now refilled, pull hand brake, press foot brake, start engine, shift through all gears.

ATF Level Check

Bring motor and transmission to operating temperature(>80°C), let AT's cooling system open (Thermostatic valve).

If the cooling system has not opened there could be not enough fluid in the transmission when it opens causing

shifting problems, slippage, going to neutral, damage can occur when driven down/uphill, in curves etc.,

while the AT pump sucks air.

AT-Fluid checking reference temperature is 80°F to 120°F (nominally 100°F).

If AT-Fluid higher 12o°F vehicle must cool down. If AT-Fluid lower 80°F, drive vehicle slowly 500m, constantly

monitor ATF temperature (OBD II Scantool), with the vehicle on the ramp (level) and the transmission fluid at

target range temperature of 90°F (32.2°C), pull hand brake, push foot

brake, move Shifter slowly through all gears, let D then R engage, then settle in park with the engine in idle.

Remove oil-level-check-plug, if to much ATF was issued, let it snarl out to the point where the snarl changes

to a fast dripping motion, then close the plug.

If not enough fluid, fill only 250ml at the time through the Fill-Plug or the mentioned

method above until the fluid flows out in a continuous deep red stream.

Screw in the AT fluid level plug as soon as the stream starts to break up into a fast dripping motion.

Info

Solenoid Body Assembly from the 5R55W/S AT will not interchange with the 5R55N AT's, fine

differences.

The internal parts of the 5R55W (Wide Ratio)/S (Sync)5R55N (Non Sync.) look almost identical, but will not interchange

with their look alike in the 5R55N (Non Sync.).

Info Tips

In some cases there could be a condition where the Shifter level is stuck in position "P", especially

when the automobile is parked on uneven, hill ground. In this case extra pressure is exerted on the

park pawl/park gear locking mechanism in the transmission. Using extra force to disengage the park pawl could

lead to un-repairable damage to the shifter's internal mechanism which is of plastic. If this is encountered

push vehicle back or forth to the take extra pressure from the park pawl, park gear.

General Service Information

General Service InformationRear axle

Rear sub-frameFront axle

Lower ball-point joint, Shock absorber bushes, Stabilizer bar links + mountsBrake disc and pads

Engine

Intake Manifold / Ignition Coils / Spark-plugs/ engine-block ventilation (elbow)Injectors

Starter system

Valve clearance, timing-chain, tensioner and glides:

With valve clearance in its tolerance,

there was no need to take the camshafts down, so tensioners and co. have to wait, the good thing is the

tensioner pumps up in 3-4 min. the rattle noise disappears.

Cruise control malfunction, emergency mode

Automatic Transmission 5R55N

Info, tips, Fail Safe ModeStall Speed Test procedure and diagnoses

Valve Body, known issues

Valve Body, Solenoid test procedures

Line Pressure Test

Self made press for pressing down clutch drum springs, checking clutch tolerance without a dial gauge

Chassis

Air ConditioningMiscellaneous repairs

Wind-shield-wiper mechanism:

Time on the lot took its toll, wind-shield-wiper shafts had seized,

uninstalled the mechanism, freed the seized shafts through the use of a good rust loosener, heat, force.

Water in Spark-plug wells 3-2 cylinder:

After days of heavy rain the engine began to misfire with

accounted trouble codes, spark-plug wells were wet, an ionized rusty red path on the ceramic insulator had developed which shorted the

HV ignition spark.

Radio:

Connected the radio controls to the multi-functional steering wheel using

an analog digital converter.