Welcome to

An Automobile Diagnosis Website

5R55N Valve Body Wet Air Test

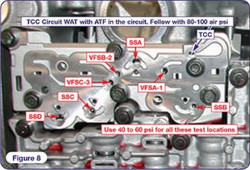

The Wet Air Test (WAT) is an effective method for identifying the condition of an 5R55N, W, and S valves bodies.

This test can be performed in the vehicle or with the transmission on the bench. When the valve body is in

a good condition, the valves will stroke and there will not be excessive leakage past the valves or

bubbling from the exhaust slots.

Though, it should be noted that excessive bore wear, visualized as leakage around the valve or slot,

can aerate the fluid during operation. This aerate fluid (suspends bubbles) will create an excessive fluid

level that then vents from the case or causes erratic pressure.

Procedure:

Remove the solenoid base plate and reattach it over the separator plate. AT-Fluid, along with low

air pressure of 40-60psi (2.75-4.0bar) can be injected (oil can) into the circuits.

To test the torque converter clutch circuit (WAT), inject (oil can), fill circuit with ATF, then

press air with a pressure of 80-100psi (5.5-7.0bar) into the circuit, see picture.

SS (A,B,C,D) Shift Solenoid (all 16-45 Ohms)

SS "A" Connector Terminals (3-16)

SS "B" (3-15)

SS "C" (3-6)

SS "D" (3-5)

PCS "A, B, C" (all 3.3-7.5 Ohm)

PCS "A" Connectors Terminal (3-11)

PCS "B" (3-1)

PCS "C" (3-4)

TTC Solenoid (3-14) (9-16 Ohm)

TOT Sensor (2-12) 32°F-68°F = 100k - 37k Ohms, 69°F-104°F = 37k - 16k Ohms

VFS Variable force solenoid

VFSA-1 goes to position 15

VFSB-2 goes to position 10 and 4

VFSC-3 goes to position 13

Solenoid Problems,

8o% of solenoid problems can be solved through thoroughly cleaning the internal plunger and guide way,

though this will not solve any electrical problems such as a defective solenoid circuit broad or an open or

shorted coil winding.

Thoroughly check electrical circuitry, coil winding, best at operating temperature and zero

temperatures (expanding, contracting), before proceeding.

Procedure:

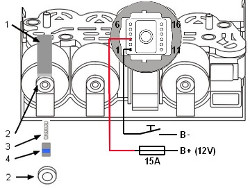

Use a chisel(1) to chip off the protection cap(2) from the solenoid.

Exactly measure the depth from the outer edge of the solenoid adjustment screw(4)to the surface!

Screw out the solenoid adjustment.

Use compressed air to retrieve spring (tiny magnet, needle with hook), do not stretch or damage, de-calibrate spring.

Clean parts and solenoids internal plunger and guide way, thoroughly.

Reassembling:

Install spring and add only a small drip of Loctite to the middle of the adjustment screw, so that it

does not run into the interior (seizing!)

Screw in the adjustment screw to the predetermined depth (exactly!)

Check each solenoid that its plunger doesn't stick (best, warm and cold)!

View the connector (see picture), assess which pin belongs to where. With the use of two lengths of wire, one

length having a fuse(15A), the other a switch, connect the ends securely to their destination points,

whereby pin3 carry’s permanent B+ while testing. Pin 1,4,5,6,11,15,16 are then one after the other

negatively tacked through switching.

General Service Information

General Service InformationRear axle

Rear sub-frameFront axle

Lower ball-point joint, Shock absorber bushes, Stabilizer bar links + mountsBrake disc and pads

Engine

Intake Manifold / Ignition Coils / Spark-plugs/ engine-block ventilation (elbow)Injectors

Starter system

Valve clearance, timing-chain, tensioner and glides:

With valve clearance in its tolerance,

there was no need to take the camshafts down, so tensioners and co. have to wait, the good thing is the

tensioner pumps up in 3-4 min. the rattle noise disappears.

Cruise control malfunction, emergency mode

Automatic Transmission 5R55N

Info, tips, Fail Safe ModeStall Speed Test procedure and diagnoses

Valve Body, known issues

Valve Body, Solenoid test procedures

Line Pressure Test

Self made press for pressing down clutch drum springs, checking clutch tolerance without a dial gauge

Chassis

Air ConditioningMiscellaneous repairs

Wind-shield-wiper mechanism:

Time on the lot took its toll, wind-shield-wiper shafts had seized,

uninstalled the mechanism, freed the seized shafts through the use of a good rust loosener, heat, force.

Water in Spark-plug wells 3-2 cylinder:

After days of heavy rain the engine began to misfire with

accounted trouble codes, spark-plug wells were wet, an ionized rusty red path on the ceramic insulator had developed which shorted the

HV ignition spark.

Radio:

Connected the radio controls to the multi-functional steering wheel using

an analog digital converter.